How are the off-flavors and taints analysed in laboratory?

The complexity of the world of taints and off-flavors means that the use of analytical methods can be compared to the example of looking for a very small needle in a large field full of haystacks, but it is one of the most exciting ones.

Here we go…

Usually it all starts with a consumer complaint, retailer complaint or with something manufacturers have discovered themselves, but it can also be an off-flavor occurring at the product development phase that needs identification.

What makes the analysis so complicated is the fact that usually the only information the lab has is the flavor of the products, and that it is most probably unacceptable to at least one person. It is well known that consumers vary in preference and definition of food flavor, including off-flavors and taints. A taint that could spell commercial disaster may only be in fact detectable by a small percentage of consumers.

Step 1: Sensory analysis

If a product that is complained about, and ideally with a reference product reaches the lab, the first step is to carry out a sensory analysis. Panel needs to assure that there is a taint or an off-flavor to the product. Sometimes the complaint has alternative reasons or the off-flavor is much less significant than expected.

Panellists that are known to be generally sensitive and reliable in their judgments.

Paired comparison, duo-trio or triangle test

Minimum 15 trained assessors

Statistical analysis (5% significance)

An important step in the sensory analysis is to distinguish if off-flavor is an off-odor or an off-taste. For that, the panelists use a nose clip. If the difference is perceived on the tongue, then it is a water-soluble compound (for example bitter off-taste), and if the difference is noticed with the nose, then it is a volatile compound. The extraction of the unwanted compound(s), and the use of instrumental analysis that follows, depending on the type of compound identified.

Extraction of taints or off-flavors from food samples

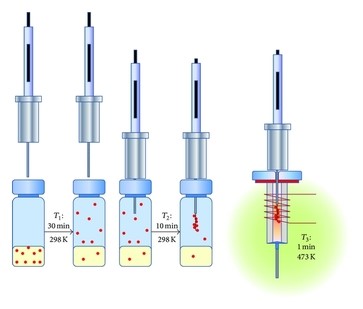

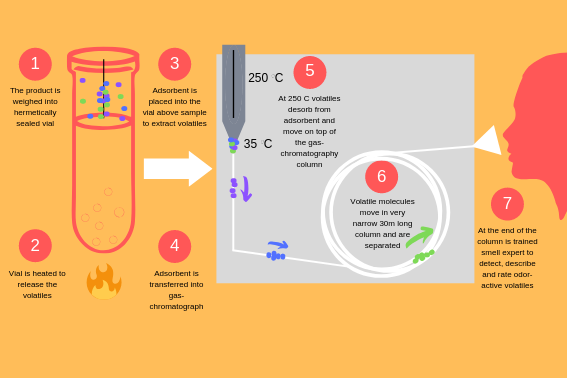

Taste compounds are extracted by solvent-solvent extraction, fractionated and analysed using liquid chromatography, while volatiles are mostly extracted using absorbent techniques and gas-chromatography. It must be said, that up to 85% of the taints and off-flavors are volatile, so gas-chromatography-olfactometry is really the main equipment used.

Gas-chromatography analysis with olfactometry

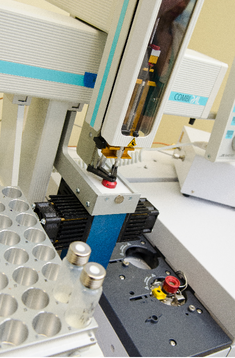

After the extraction, the absorbent is injected into gas-chromatography with a narrow capillary column of 30 meters. The aim is to separate all the extracted volatiles, so they can be assessed one-by-one.

Separation occurs due to the capillary forces, and from the fact that smaller molecules move faster than the bigger ones.

To detect off-flavors, particularly taints, that are present in very low concentrations, using a human nose as a detector works the best. It is more sensitive and humans can well describe odors if they are trained.

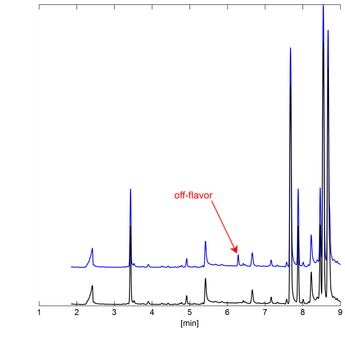

After analysing both tainted and reference products, it is later possible to compare the analysis and filter out possible candidates for causing the fault.

Final identification of off-flavors or taints

Sometimes it can be just one compound, but which compound it is? Sometimes, identification is possible if we are lucky enough, or possess high-end instruments like comprehensive and heart-cut gas-chromatography/mass-spectrometry. If not, searching for literature and common chemistry knowledge might help. Identification has to be carried on the basis of trial and error.

Finally, the identified off-flavor or taint compound needs to be confirmed by adding it (or them) at the same concentration to the reference product. The sensory panel is used again to assure that both products are the same; the tainted product and the reference product with added compound(s). Only then it is possible to confirm the identification of the off-flavor.

Identified off-flavor – happy ending?!

One might guess that this is a happy ending. Unfortunately, the hardest part of the investigation is just about to begin. Two important questions from a manufacturer’s perspective are, ‘where did it come from?’ and ‘How to avoid it in the future?’

Now the definition between taints and off-flavors comes in handy – oxidation, degradation, migration, light induction, microbiological, enzymatic reactions etc. Scientific literature and databases are definitely here to help. Flavodata is one of them, as it has all published and unpublished off-flavor incidents filtered out. You can create an account here, for free.

Sometimes, additional analysisneeds to be carried out in order to confirm the forming mechanisms, and it isnot a rare case that the ‘murderer’ has been identified, but not the way s/he committedthe crime.